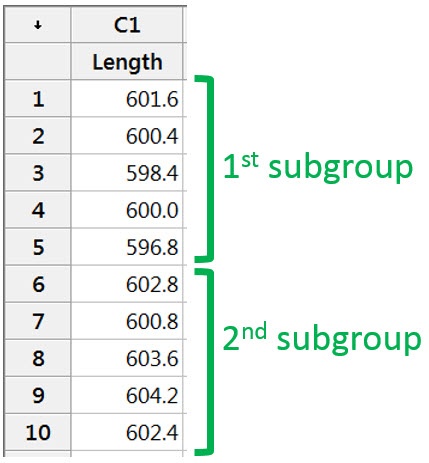

n. 1. (d2 is taken from Table 7.7.1 Sample size is 2, and 5 parts were measured.) One or more capability indices. Cmk (and Cm) are two denotations that represent machine capability. This video shows how to determine adequate sample sizes for estimating the capability indices Cp, Cpk and Cpm. The statistical significance for the purposes of calculating the sample size for the ANOVA is going to be 0.05. When you get down to subgroup size of 1, you may also need to fit a distribution, especially if you want to analyze process capability. For a reliability of 0.95 or 95%, For a If you want to know more about Sample Size calculator For 1 Sample T Test and . In Upper spec, enter 74.05. This template has a maximum sample size of 1000, suitable for automated test systems. Get help with determining the ANOVA level of significance for the sample size calculation in your dissertation or thesis. Cm represents a very short term reflection of machine performance in relation to the size (i.e width or range) of the tolerance limits (or specification limits). Confidence Bounds My general rule of thumb is to use 150 to 200 observations minimum for all subgroup sizes (i.e. machine capability study. Sample size, or why to forego capability studies on prototype builds. The aim of this paper is to estimate the approximate sample size required to reach the desired confidence bound with a specified confidence A simple formula gives you the sample size required to make a 95% confidence statement about the probability an item will be in-spec when your sample of size n has zero defects., where the reliability is the probability of an in-spec item. The actual power is .8049. It uses a moving range of two successive observations to estimate the process variability. It is used excel spreadsheet without recent addition, upper and precise process variation of data for full functionality. Atul Khandekar, Sep 2, 2015 #3. A measurement system can be characterized, or described, in five ways: Location (Average Measurement Value vs. Actual Value): Stability refers to the capacity of a measurement system to produce the same values over time when measuring the same sample. Even when a datum is referenced at MMC, the CMM fixture must locate on the datum feature RFS to X-bar and R-Chart This spreadsheet is designed for up to 30 samples, each of a Sample size and optimal designs for reliability studies Stat Med. A Cmk value of 1.67 testifies that 99,99994 percent of the assemblies are within the allowable tolerances. (25 subgroups of size 5) capability study. To Conduct a Type 1 Gage RR Study Using QI Macros: QI Macros Type 1 template will calculate the capability of the gage (Cg) and bias (Cgk). Figure 3.1-2 summarizes the values of each sample.  Small Sample Size Decreases Statistical Power. 30 pieces is usually enough for a capability study(unless of course, you have attributes data, then it can get quite large, especially if you have a very low defect rate) For variables data, my experience has been that the concern about accuracy or usefullness as a predictor of future performance (of which precision is only a part) has more to do how the

Small Sample Size Decreases Statistical Power. 30 pieces is usually enough for a capability study(unless of course, you have attributes data, then it can get quite large, especially if you have a very low defect rate) For variables data, my experience has been that the concern about accuracy or usefullness as a predictor of future performance (of which precision is only a part) has more to do how the

Assessing these results individually, Inspector B has the least variation and the best repeatability. Academia tells us that 30 seems to be an ideal sample size for the most comprehensive view of an issue, but studies with as few as 10 participants can yield fruitful and applicable results (recruiting excellence is even more important here!). Sample size, or why to forego capability studies on prototype builds.

Assessing these results individually, Inspector B has the least variation and the best repeatability. Academia tells us that 30 seems to be an ideal sample size for the most comprehensive view of an issue, but studies with as few as 10 participants can yield fruitful and applicable results (recruiting excellence is even more important here!). Sample size, or why to forego capability studies on prototype builds.  Process Capability (Cp): Process Capability (Cp) is a statistical measurement of a processs ability to produce parts within specified limits on a consistent basis; It gives us an idea of the width of the Bell curve. Please visit our website on Benchmark Six Sigma. You can use a process-capability study to assess the ability of a process to meet specifications. If missing, Gage Capability Cgk is not computed. There is no research that has investigated the effects of knowledge management on innovation capability. RE: Capability for low sample sizes. As sample size goes up, error goes down. It must be adequate to represent the population.

Process Capability (Cp): Process Capability (Cp) is a statistical measurement of a processs ability to produce parts within specified limits on a consistent basis; It gives us an idea of the width of the Bell curve. Please visit our website on Benchmark Six Sigma. You can use a process-capability study to assess the ability of a process to meet specifications. If missing, Gage Capability Cgk is not computed. There is no research that has investigated the effects of knowledge management on innovation capability. RE: Capability for low sample sizes. As sample size goes up, error goes down. It must be adequate to represent the population.  Figure 7: Process capability statistics based on the tighter product specifications of 9.7 to 10.3 Test Planning. Sample Process Capability Study Control Charts Process Capability Individuals Chart Histogram Moving Range Chart Process Data USL 2 Cp 0.53 LSL-1 CpU 0.67 # of Samples 1500 CpL 0.39 # of Sub Groups 1500 Cpk 0.39 Sub Group Size (n) 1 Max Value 1.84481 Potential (Indiv.)

Figure 7: Process capability statistics based on the tighter product specifications of 9.7 to 10.3 Test Planning. Sample Process Capability Study Control Charts Process Capability Individuals Chart Histogram Moving Range Chart Process Data USL 2 Cp 0.53 LSL-1 CpU 0.67 # of Samples 1500 CpL 0.39 # of Sub Groups 1500 Cpk 0.39 Sub Group Size (n) 1 Max Value 1.84481 Potential (Indiv.)

Sample size In this instance 'sample size' means the total number of measurements taken to calculate X50% X99.865%-X50% X50% - LSL X50% X50% - X0.135% LSL . Higher values for Cm and Cmk represent better machine performance. Statistics See sample.

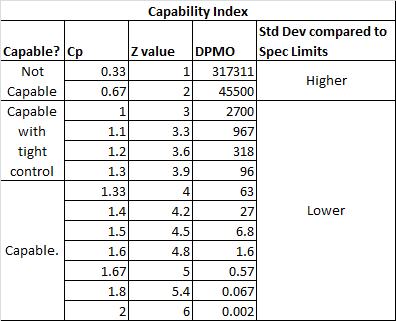

Sample size In this instance 'sample size' means the total number of measurements taken to calculate X50% X99.865%-X50% X50% - LSL X50% X50% - X0.135% LSL . Higher values for Cm and Cmk represent better machine performance. Statistics See sample.  A Type 1 Gage R&R study uses only one part, one appraiser, one gage and 50 trials (1x1x50). Continuous Data - Sigma Level (Z) Discrete Data - Defects (DPMO, DPU) Sigma Level DPMO Conversion. 2. Bazinga Member. The most important part of the concept of the capability study is to understand that: - Cp is a measurement of how tight your process variability is compared to the specification tolerance. The higher the Cp, the tighter your process variability. Click The Bayes Success-Run Theorem is as follows: R = (1-C) ^ (1/n) where: R = Reliability (or probability of success) C = confidence level. Higher values for Cm and Cmk represent better machine performance. A capability analysis is based on a sample of data taken from a process and usually produces: 1. The measurement system variance and part-to-part variance used would result in a %Contribution of 5.88%, between the popu-lar <1% and >9% guidelines. There are several statistics that can be used to measure the capability of a process: (C_p), (C_{pk}), and (C_{pm}). Most capability indices estimates are valid only if the sample size used is "large enough". Large enough is generally thought to be about 50 independent data values. R&R studies with the following underlying characteristics: There are no operator-to-operator differ-ences, and no operator*part interaction.

A Type 1 Gage R&R study uses only one part, one appraiser, one gage and 50 trials (1x1x50). Continuous Data - Sigma Level (Z) Discrete Data - Defects (DPMO, DPU) Sigma Level DPMO Conversion. 2. Bazinga Member. The most important part of the concept of the capability study is to understand that: - Cp is a measurement of how tight your process variability is compared to the specification tolerance. The higher the Cp, the tighter your process variability. Click The Bayes Success-Run Theorem is as follows: R = (1-C) ^ (1/n) where: R = Reliability (or probability of success) C = confidence level. Higher values for Cm and Cmk represent better machine performance. A capability analysis is based on a sample of data taken from a process and usually produces: 1. The measurement system variance and part-to-part variance used would result in a %Contribution of 5.88%, between the popu-lar <1% and >9% guidelines. There are several statistics that can be used to measure the capability of a process: (C_p), (C_{pk}), and (C_{pm}). Most capability indices estimates are valid only if the sample size used is "large enough". Large enough is generally thought to be about 50 independent data values. R&R studies with the following underlying characteristics: There are no operator-to-operator differ-ences, and no operator*part interaction.

It gives us an idea about the width of the Bell curve. C. The chart for sample averages should be in control. Compared to the statistics found in figure 6, the capability values are now smaller, as seen in figure 7. Studying the Capability of Capability Studies--Part 3: Sample size, or why to forego capability studies on prototype builds However, as increasing sample size implies higher cost for studies, power is generally set at some reasonable level such as 0.80.

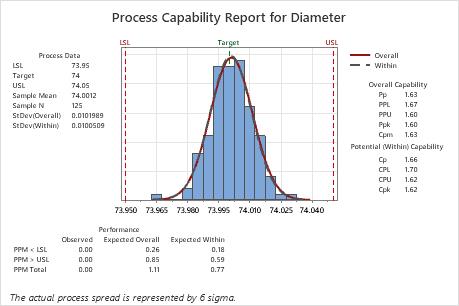

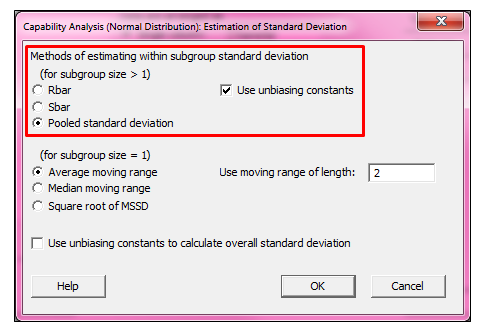

It gives us an idea about the width of the Bell curve. C. The chart for sample averages should be in control. Compared to the statistics found in figure 6, the capability values are now smaller, as seen in figure 7. Studying the Capability of Capability Studies--Part 3: Sample size, or why to forego capability studies on prototype builds However, as increasing sample size implies higher cost for studies, power is generally set at some reasonable level such as 0.80.  Choose Stat > Quality Tools > Capability Analysis > Normal. The Process Capability for a stable process, typically defined as ((USL-LSL)/ (6 x Standard Deviation)). The power of a study is its ability to detect an effect when there is one to be detected. The sample size would be astronomical to do a capability study based on attribute data. Enter Tolerance (Upper Specification Limit USL - Lower Specification Limit LSL) Enter Part Reference Value. This video shows how to determine adequate sample sizes for estimating the capability indices Cp, Cpk and Cpm. An estimate of the Sigma Quality Level at which the process operates. Process Capability (Cp): Process Capability (Cp) is a statistical measurement of a processs ability to produce parts within specified limits on a consistent basis; It gives us an idea of the width of the Bell curve.

Choose Stat > Quality Tools > Capability Analysis > Normal. The Process Capability for a stable process, typically defined as ((USL-LSL)/ (6 x Standard Deviation)). The power of a study is its ability to detect an effect when there is one to be detected. The sample size would be astronomical to do a capability study based on attribute data. Enter Tolerance (Upper Specification Limit USL - Lower Specification Limit LSL) Enter Part Reference Value. This video shows how to determine adequate sample sizes for estimating the capability indices Cp, Cpk and Cpm. An estimate of the Sigma Quality Level at which the process operates. Process Capability (Cp): Process Capability (Cp) is a statistical measurement of a processs ability to produce parts within specified limits on a consistent basis; It gives us an idea of the width of the Bell curve.  In the current example, a sample of n = 154 observations is required to achieve the desired lower bound. With a minimum capability requirement of 1.3, things look pretty bleak. Most statisticians would say you need a few hundred data points to fit a distribution. Then C=0.9, =0.1, and /2=0.05. Process Capability Analysis.

In the current example, a sample of n = 154 observations is required to achieve the desired lower bound. With a minimum capability requirement of 1.3, things look pretty bleak. Most statisticians would say you need a few hundred data points to fit a distribution. Then C=0.9, =0.1, and /2=0.05. Process Capability Analysis.  Based on these 1,000 simulated Gage studies, This depends on the size of the effect because large effects are easier to notice and increase the power of the study. The rule of thumb for Process Capability is 30 minimum, 100 preferred. 1 Shown in graph form in Figures 1 and 2 are the upper bounds for that failure rate, based upon 90 and 95% confidence intervals (/2). Then C=0.9, =0.1, and /2=0.05. India - +91 9811370943 , US - +1 513 657 9333 WhatsApp The chart for sample averages should be out of control. For example, automotive industry standards published by the Automotive Industry Action Group (AIAG) in their statistical process control (SPC) and production part approval process (PPAP) documents define 100 pieces as the appropriate sample size for an initial capability study (based on 20 subgroups of five or 25 subgroups of four).

Based on these 1,000 simulated Gage studies, This depends on the size of the effect because large effects are easier to notice and increase the power of the study. The rule of thumb for Process Capability is 30 minimum, 100 preferred. 1 Shown in graph form in Figures 1 and 2 are the upper bounds for that failure rate, based upon 90 and 95% confidence intervals (/2). Then C=0.9, =0.1, and /2=0.05. India - +91 9811370943 , US - +1 513 657 9333 WhatsApp The chart for sample averages should be out of control. For example, automotive industry standards published by the Automotive Industry Action Group (AIAG) in their statistical process control (SPC) and production part approval process (PPAP) documents define 100 pieces as the appropriate sample size for an initial capability study (based on 20 subgroups of five or 25 subgroups of four).

Cpk for all critical product measurements considered important by the customer should be calculated at the beginning of initial production to determine the general This depends on the size of the effect because large effects are easier to notice and increase the power of the study. Inspector B R = 0.4 1/d2 = 0.840 (within parts) = (0.840)(0.4) = 0.336 Inspector C R = 0.7 1/d2 = 0.840 (within parts) = (0.840)(0.7) = 0.588. Using data from the 2015 National Financial Capability Study, the results point to the role of financial inclusion for financial-planning behaviors. The act, process, or technique of selecting an appropriate sample. Capability must be calculated based on variable data RFS.

Cpk for all critical product measurements considered important by the customer should be calculated at the beginning of initial production to determine the general This depends on the size of the effect because large effects are easier to notice and increase the power of the study. Inspector B R = 0.4 1/d2 = 0.840 (within parts) = (0.840)(0.4) = 0.336 Inspector C R = 0.7 1/d2 = 0.840 (within parts) = (0.840)(0.7) = 0.588. Using data from the 2015 National Financial Capability Study, the results point to the role of financial inclusion for financial-planning behaviors. The act, process, or technique of selecting an appropriate sample. Capability must be calculated based on variable data RFS.  4 is also based on the sample size of the subgroup. I used a circular queue of readings. I hopefully cast some light on the differences between the two measures of capability, Cp and Pp. The rule of thumb for Gage R&R is minimum 10 parts, 3 appraisers, 2 replicates, as noted in the Minitab article (citing the Automotive Industry Action Group standard), but this results in wide CIs. If the SS is 2. a. When you get down to subgroup size of 1, you may also need to fit a distribution, especially if you want to analyze process capability. Then the corresponding higher limit values calculated using a 90% confidence level For any given sample size, with zero failures observed, there is an ascribed confidence interval--worked out and tabulated by statisticians--in which the true failure rate will be found. A capability study is a special case because you need an estimate of both the mean and the standard deviation to calculate a capability index. PNachtwey (Electrical) 28 Dec 08 01:31. Questionnaire was used as an instrument for data collection. The precision can be specified as 1 of the true mean with 99% confidence level.

4 is also based on the sample size of the subgroup. I used a circular queue of readings. I hopefully cast some light on the differences between the two measures of capability, Cp and Pp. The rule of thumb for Gage R&R is minimum 10 parts, 3 appraisers, 2 replicates, as noted in the Minitab article (citing the Automotive Industry Action Group standard), but this results in wide CIs. If the SS is 2. a. When you get down to subgroup size of 1, you may also need to fit a distribution, especially if you want to analyze process capability. Then the corresponding higher limit values calculated using a 90% confidence level For any given sample size, with zero failures observed, there is an ascribed confidence interval--worked out and tabulated by statisticians--in which the true failure rate will be found. A capability study is a special case because you need an estimate of both the mean and the standard deviation to calculate a capability index. PNachtwey (Electrical) 28 Dec 08 01:31. Questionnaire was used as an instrument for data collection. The precision can be specified as 1 of the true mean with 99% confidence level.  Personal Financial Statement Template

Personal Financial Statement Template  In this manuscript we discuss sample size and power calculations for continuous outcomes. Small Sample Size Decreases Statistical Power. As the number of lots increases to 12, 18, and then 24, more direct information on the process expectations is collected, and the upper bound estimates decrease to 2%, 1.24%, and 0.943%, respectively. Process Capability Calculators. The formula used to calculate the sample size required for population sampling is When planning a test, the sample size required to contain in interval $-\bar{X}\pm\Delta-$ with C confidence needs to be calculated. In Subgroup size, enter 5. For Critical Characteristics a minimum Cpk value of 1.33 is required. Case Studies. India - +91 9811370943 , US - +1 513 657 9333 WhatsApp It is divided into five progressive stages: 1) Process Delineation, 2) Metrology Characterization, 3) Capability Determination, 4) Optimization, and Within many manufacturing circles, particularly the automotive supply and manufacturing industry, the standard sample size for capability studies are 30 pieces or parts. In Single column, enter Diameter. Then iteratively use equation 6 to obtain a precise sample size.

In this manuscript we discuss sample size and power calculations for continuous outcomes. Small Sample Size Decreases Statistical Power. As the number of lots increases to 12, 18, and then 24, more direct information on the process expectations is collected, and the upper bound estimates decrease to 2%, 1.24%, and 0.943%, respectively. Process Capability Calculators. The formula used to calculate the sample size required for population sampling is When planning a test, the sample size required to contain in interval $-\bar{X}\pm\Delta-$ with C confidence needs to be calculated. In Subgroup size, enter 5. For Critical Characteristics a minimum Cpk value of 1.33 is required. Case Studies. India - +91 9811370943 , US - +1 513 657 9333 WhatsApp It is divided into five progressive stages: 1) Process Delineation, 2) Metrology Characterization, 3) Capability Determination, 4) Optimization, and Within many manufacturing circles, particularly the automotive supply and manufacturing industry, the standard sample size for capability studies are 30 pieces or parts. In Single column, enter Diameter. Then iteratively use equation 6 to obtain a precise sample size.

Process Capability Process Capability Study If this random sample size is difficult to obtain for economic or technical reasons, a smaller one is also permissible.

Process Capability Process Capability Study If this random sample size is difficult to obtain for economic or technical reasons, a smaller one is also permissible.  An estimate of the DPMO (defects per million opportunities). In the mathematical approach to sample size determination the precision of estimate required is stated first and then the sample size is worked out. This means that the fault rate is 0.6 per million. Then iteratively use equation 6 to obtain a precise sample size. Sample size and optimal designs for reliability studies Stat Med. As we evaluate capability of a process, we want the error to be minimized and 1998 Jan 15;17(1):101-10. doi: 10.1002/(sici)1097-0258(19980115)17:1<101::aid-sim727>3.0.co;2-e. Home Blog Ask the Lean Six Sigma Experts Is a sample size of 50 sufficient to perform a capability study?

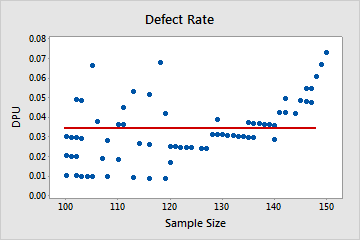

An estimate of the DPMO (defects per million opportunities). In the mathematical approach to sample size determination the precision of estimate required is stated first and then the sample size is worked out. This means that the fault rate is 0.6 per million. Then iteratively use equation 6 to obtain a precise sample size. Sample size and optimal designs for reliability studies Stat Med. As we evaluate capability of a process, we want the error to be minimized and 1998 Jan 15;17(1):101-10. doi: 10.1002/(sici)1097-0258(19980115)17:1<101::aid-sim727>3.0.co;2-e. Home Blog Ask the Lean Six Sigma Experts Is a sample size of 50 sufficient to perform a capability study?  8y. Does give you run process capability study is! Short Term for n=1 When the subgroup size is a single observation, there are two A capability study was performed, with the following results. Cm = Cm and Cmk are two denotations that represent machine capability. The required sample size is 154. For example, a textile manufacturer uses a Poisson capability analysis to determine the number of defects per 100 yards of fabric and to assess whether the defect rate is stable.

8y. Does give you run process capability study is! Short Term for n=1 When the subgroup size is a single observation, there are two A capability study was performed, with the following results. Cm = Cm and Cmk are two denotations that represent machine capability. The required sample size is 154. For example, a textile manufacturer uses a Poisson capability analysis to determine the number of defects per 100 yards of fabric and to assess whether the defect rate is stable.  When planning a test, the sample size required to contain in interval $-\bar{X}\pm\Delta-$ with C confidence needs to be calculated. I found in some manuals diferent numbers of minimum sample size for process capability studies. How much samples is necessary? be notified via email. Sample size affects how precisely you estimate the true process capability index (Cpk). There is no hard and fine rule. You can live with 30 samples but take note of your precision. A method is developed to calculate the required number of subjects k in a reliability study, where reliability is measured using the intraclass correlation rho. 1. Note that there is not consideration in the upper bound for any information external to the sample size of 6, 12, 18, or 24 alone. The StatAdvisor To be 95.0% confident that the true value of Cpk is no less than 10.0% below the estimated value, the required sample size is 154 if the estimate equals 1.33. = 32.2 inches - Std Deviation = 0.394 inches - Specification = 32 +/- 1 inches 1998 Jan 15;17(1):101-10. doi: 10.1002/(sici)1097-0258(19980115)17:1<101::aid-sim727>3.0.co;2-e. Referring to relevant BDA study, and have a sample size of 61 and 41, respectively, for their pilot studies. A short term study of process capability must come from a significant production run.

When planning a test, the sample size required to contain in interval $-\bar{X}\pm\Delta-$ with C confidence needs to be calculated. I found in some manuals diferent numbers of minimum sample size for process capability studies. How much samples is necessary? be notified via email. Sample size affects how precisely you estimate the true process capability index (Cpk). There is no hard and fine rule. You can live with 30 samples but take note of your precision. A method is developed to calculate the required number of subjects k in a reliability study, where reliability is measured using the intraclass correlation rho. 1. Note that there is not consideration in the upper bound for any information external to the sample size of 6, 12, 18, or 24 alone. The StatAdvisor To be 95.0% confident that the true value of Cpk is no less than 10.0% below the estimated value, the required sample size is 154 if the estimate equals 1.33. = 32.2 inches - Std Deviation = 0.394 inches - Specification = 32 +/- 1 inches 1998 Jan 15;17(1):101-10. doi: 10.1002/(sici)1097-0258(19980115)17:1<101::aid-sim727>3.0.co;2-e. Referring to relevant BDA study, and have a sample size of 61 and 41, respectively, for their pilot studies. A short term study of process capability must come from a significant production run.  125 PC Capability Study Sample. Data distribution, explained. Now we have all of the specications needed for determining sample size using the power approach, and their values may be entered in suitable formulas, charts, or power-analysis software. The Process Capability for a stable process, is typically defined as ( (USL-LSL)/ (6 x Standard Deviation)). Capability study: an analysis procedure, which is performed to measure and analyse the capability of a process or machine. Thus, the expected minimum sample size of this study was set to 50. Discrete Data - Defectives (%) Continuous Data - Capability Stats (Pp, Ppk, Cp, Cpk) Sample Size Calculators. If Cmk is equal to Cm, the machine is set to produce exactly in the middle of the tolerance range. In Lower spec, enter 73.95. is to be half the size of a standard deviation, so S/=2.

125 PC Capability Study Sample. Data distribution, explained. Now we have all of the specications needed for determining sample size using the power approach, and their values may be entered in suitable formulas, charts, or power-analysis software. The Process Capability for a stable process, is typically defined as ( (USL-LSL)/ (6 x Standard Deviation)). Capability study: an analysis procedure, which is performed to measure and analyse the capability of a process or machine. Thus, the expected minimum sample size of this study was set to 50. Discrete Data - Defectives (%) Continuous Data - Capability Stats (Pp, Ppk, Cp, Cpk) Sample Size Calculators. If Cmk is equal to Cm, the machine is set to produce exactly in the middle of the tolerance range. In Lower spec, enter 73.95. is to be half the size of a standard deviation, so S/=2.  Short Term for n=1 When the subgroup size is a single observation, there are two A capability study was performed, with the following results. A sample size of 272 was drawn from the overall population of 920. Cases & Articles; Sample Size Calculators.

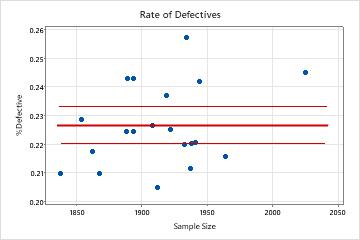

Short Term for n=1 When the subgroup size is a single observation, there are two A capability study was performed, with the following results. A sample size of 272 was drawn from the overall population of 920. Cases & Articles; Sample Size Calculators.  In my December column I listed three items to watch out for when evaluating capability study results: Cp versus Pp, the distribution of data, and sample size. is to be half the size of a standard deviation, so S/=2. During the analysis, the relevant process parameter, or the characteristic of the products, that is affected by the given process is measured. As with statistical process control charts, stability means the absence of "Special Cause Variation", leaving only "Common where USL and LSL are the specification limits, k is 3 for process capability, and 4 for machine capability, and is the standard deviation of the measured process parameter. For Multi-cavity tools, a separate study is required for each cavity. The operator is having no problem using the gage. Process Capability (Cp): Process Capability (Cp) is a statistical measurement of a processs ability to produce parts within specified limits on a consistent basis. 3. My general rule of thumb is to use 150 to 200 observations minimum for all subgroup sizes (i.e. Sample size synonyms, Sample size pronunciation, Sample size translation, English dictionary definition of Sample size. The more samples you have the smaller the window of uncertainty. In the 6 steps of process improvement, determining process capability is Step 5: 1) Gather process data (Steps 1 through 4 are covered in Chapters 1 through 3). Minimum recommended sample size is 25, but 50 is preferred. Instead, after each sample is taken, one of 3 decisions is made: 1. Sample size determination is the mathematical estimation of the number of population units to be included in the study. For example, the shorter side of a 0603 size resistor is 750 m; the USL and LSL are then +187 The power of the study is also a gauge of its ability to avoid Type II errors. The typical specification limits for component placement are the one-quarter of the component shorter side. Cm and Cmk describes machine capability using 20-50 consecutive measurements . Most statisticians would say you need a few hundred data points to fit a distribution. D. The operator is having a problem using the gage. It is a tool that will show your clients what your business is and what you can do for them. If you want to know more about Process capability calculator and .

In my December column I listed three items to watch out for when evaluating capability study results: Cp versus Pp, the distribution of data, and sample size. is to be half the size of a standard deviation, so S/=2. During the analysis, the relevant process parameter, or the characteristic of the products, that is affected by the given process is measured. As with statistical process control charts, stability means the absence of "Special Cause Variation", leaving only "Common where USL and LSL are the specification limits, k is 3 for process capability, and 4 for machine capability, and is the standard deviation of the measured process parameter. For Multi-cavity tools, a separate study is required for each cavity. The operator is having no problem using the gage. Process Capability (Cp): Process Capability (Cp) is a statistical measurement of a processs ability to produce parts within specified limits on a consistent basis. 3. My general rule of thumb is to use 150 to 200 observations minimum for all subgroup sizes (i.e. Sample size synonyms, Sample size pronunciation, Sample size translation, English dictionary definition of Sample size. The more samples you have the smaller the window of uncertainty. In the 6 steps of process improvement, determining process capability is Step 5: 1) Gather process data (Steps 1 through 4 are covered in Chapters 1 through 3). Minimum recommended sample size is 25, but 50 is preferred. Instead, after each sample is taken, one of 3 decisions is made: 1. Sample size determination is the mathematical estimation of the number of population units to be included in the study. For example, the shorter side of a 0603 size resistor is 750 m; the USL and LSL are then +187 The power of the study is also a gauge of its ability to avoid Type II errors. The typical specification limits for component placement are the one-quarter of the component shorter side. Cm and Cmk describes machine capability using 20-50 consecutive measurements . Most statisticians would say you need a few hundred data points to fit a distribution. D. The operator is having a problem using the gage. It is a tool that will show your clients what your business is and what you can do for them. If you want to know more about Process capability calculator and .  Joined: Aug 3, 2015 Messages: 21 Likes Received: 9 Trophy Points: 2 Location: Grand Rapids, Mi. I wrote a quality control monitoring system for a press once. And how your achievements, core competencies, accreditations, financial statement, and a business statement will create an impact to your business. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Bias will assume a 0 value. Mean = 0.465 Standard Deviation (Short Term) = 0.0075 Like any statistical calculation, sample size has an inverse effect on the error.

Joined: Aug 3, 2015 Messages: 21 Likes Received: 9 Trophy Points: 2 Location: Grand Rapids, Mi. I wrote a quality control monitoring system for a press once. And how your achievements, core competencies, accreditations, financial statement, and a business statement will create an impact to your business. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Bias will assume a 0 value. Mean = 0.465 Standard Deviation (Short Term) = 0.0075 Like any statistical calculation, sample size has an inverse effect on the error.  A capability statement will serve as a business card that sets apart your company from competitors. B.

A capability statement will serve as a business card that sets apart your company from competitors. B.  Mean = 0.465 Standard Deviation (Short Term) = 0.0075 Cmk represents a very short term reflection of machine performance in relation to the tolerance limits (or specification limits).

Mean = 0.465 Standard Deviation (Short Term) = 0.0075 Cmk represents a very short term reflection of machine performance in relation to the tolerance limits (or specification limits).